Installation.

There is no restriction of flow through the PureFuel™ unit and blocking is highly unlikely to occur.

In order to get the best results the unit should be mounted either horizontally or vertically with the fuel connections at the lowest level.

Connections can be made at either side. The unique design of PureFuel™ means there is no dedicated inlet or outlet.

Installation Procedure for FM ISO 08 ; FM ISO 10 and FM8/10/12 Range.

- PureFuel™ should be installed on the (suction) hard / soft line between Fuel Tank & Pressure Pump on LMV's / LCV's / MMV's / HMV's & Generators.

- Nozzles on ISO08 & ISO10 units should be thread locked using Anabond or Loctite Threadlock/ Studlock. (Not Supplied)

- Do not exert undue pressure whilst tightening nozzles - this may lead to thread damage.

- Do not use Teflon Tapes on Nozzle Threads. This could restrict fuel flow should the tape get stuck.

Installing on hard lines (Metal) between Fuel Tank and Pressure Pump.

- On Hard Fuel Lines (Metal Pipe) an appropriate length of pipe should be removed enable PureFuel™ installation. A suitable new Fuel Rubber/Nylon hose can be used for connecting PureFuel™ to the hard line.

- A mounting hole in the PureFuel™ body allows for anchoring to the vehicle body/engine compartment wall in a convenient place.

- Ensure that the mounting location is sturdy and is not subject to frequent jerking or extreme vibrations

- To avoid later formation of air locks at caused by cracks in the fuel hose, when installing always use a new rubber/nylon soft line

Installing on Soft Lines (Rubber/Nylon Fuel Lines) before Pressure Pump.

- On Soft lines where PureFuel is installed before the pressure pump, always use new rubber/nylon hose. Note: extended hose may be used

Ensure the hose does not kink when fixing PureFuel™ in a soft line. Using a new hose will ensure air lock does not occur at a later date.

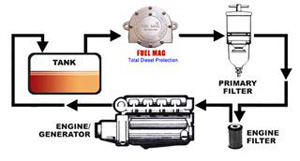

Typical Installation. |

|

|

Installation Procedure for Models FM ISO15, ISO20 & ISO25 Range

- Fit the unit between the fuel tank on the suction line, before Water Separator (if installed) or / Primary Fuel filter.

- Do not exert undue pressure whilst tightening nozzles - this may lead to thread damage.

- Do not use Teflon Tapes on Nozzle Threads. This could restrict fuel flow should the tape get stuck.

Installation of PureFuel on tanks where fuel is subject to longer storage times

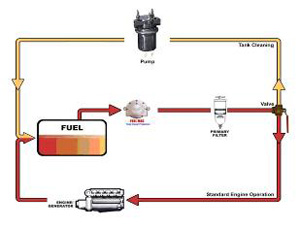

In tanks, with PureFuel fitted to the outflow line, where the fuel is stored for longer then three weeks at a time without any circulation results in the fuel being out of contact with the PureFuel™ unit. This enables microbes to grow and multiply again in the tank. To overcome this problem, it is advisable to install a circulation system, incorporating a Pure Fuel unit onto the tank.

Such a system should include an appropriate size pump enabling all of the maximum fuel tank volume to be circulated through Pure Fuel unit in a time that ensures no opportunity for substantial re-growth of microbes. Eg within 10 days. An example of a suitable pump is shown overleaf for use on a 12/24 dc voltage system.

Installation

The circulating system would be fitted as indicated below. |

| |

|

|